Interview with Alexander Bont, owner of the Australian Brand

Bont was founded in 1975. The Australian brand celebrates its 40th anniversary. We met Alexander Bont to learn more about the past ant the future of Bont...

Par alfathor

Interview with Alexander Bont after the 40th anniversary of the brand in 2015

Hello Alex, thank you for your time. Bont : Is it a family story?

My parents Sara and Inze Bont met ice skating and were friends for many years before they started dating. My mother’s uncle owned an ice rink in Sydney (Australia) so she spent a lot of her weekends helping out at the snack bar. My father watched figure skating on TV at the Olympics when he was very young and he fell in love with skating.

” So the two of them met at the skating rink and when I was born I was born into a skating family. I started skating at the age of 2 and by the age of 16, I was in the Australian national team.

Alexander Bont

My father wanted me to experience all forms of skating so I used to race short track ice, long track ice, quads and also inlines. I spent my holidays helping my father make skates and when I went to university I chose subjects that would help my career working for the family business.

Bont is celebrating its 40th birthday in 2015. How was the brand born? How did it start?

As my parents spent a lot of time at the skating rink they got into speed skating in their teenage years. In the 1960’s people did speed skating for fun and it was not super competitive. The boots were made of leather and the blades were riveted in place so you could not move them.

My father had an idea to use fibreglass around the heel to support the ankle and the idea worked really well. Soon everyone was asking my father to fiberglass their boots and international skaters were asking my father to buy leather boots, fiberglass them and ship them overseas.

In the early 1970s, Sara and Inze Bont were casual speed skaters. They participated in competitions for fun. Inze then made leather belts and handbags.

In 1974, the most popular brand on the market was Planert Skates (pictured below).

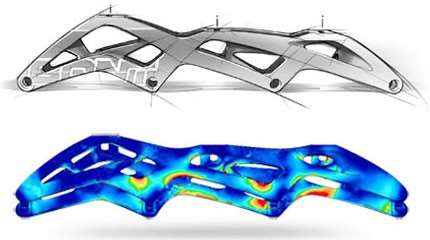

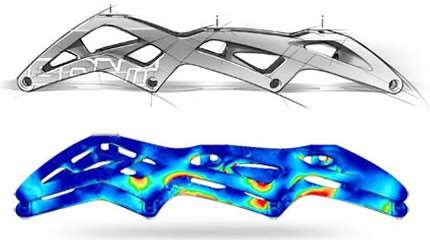

My father Inze had noticed that the shoe lacked support. So, he then had the idea of using fiberglass around the ankle to reinforce the boot. My father spent about a year playing around with plaster molds and learning how to sand the plaster foot so it would be comfortable, before he made his first boot in 1974. This new boot was a revolution because it introduced adjustable blades, 165mm mounting, heat moldable resins and fiberglass boots all in the one new product. This was the beginning of Bont Skates.

And I imagine he got a strong demand afterwards…

Yes. Other skaters saw how fast Inze was skating. They asked him to make these modified skates. He would then equip their leather shoes with fiberglass and send them to the other side of the world. Inze soon began making his own shoes and developed a final wooden mold based on his own foot. In 1975, he began selling his own brand of short track shoes from his home in Sydney, Australia.

In 1978, ice skaters used Inze skate models in the summer to train with inline skates. Then Inze developed his business with Dennis Pennington. They bought urethane skateboard wheels and sand them so they were less square and more pointy.

These inline skates were the first to look like modern inline skates and the world’s first mass-produced inline skates.

How did the market develop during this period?

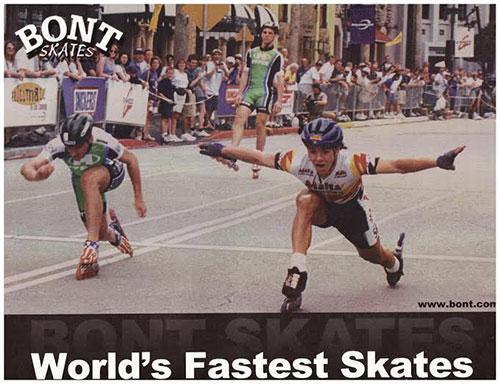

In the mid-1980s, Kryptonics released its 72mm wheel. So roller skaters in the United States and Australia mounted inline frames from brands such as Darkstar, Mogema and Raps on short-track shoes. Bont inline skates were so popular in the 1980s that event organizers often told skaters over loudspeakers to “put on their Bonts.”

Races often had up to 300 inline speed skaters on the start line. They all wore Bont skates, before American brand Miller began making its own inline speed skates. Inline skates offered more speed than traditional roller skates.

Bont improved traditional speed skates in a similar way in the late 1970s. It was the first company to produce traditional skates made from fiberglass composites.

It was a revolution in the skating world, the beginning of custom boots. It had a thermoformable resin, a mounting distance of 165mm, a fiberglass structure, all in a single product. This is how Bont began.

The brand started with ice skating, then quad and inline, and finally cycling shoes. How do you explain this evolution?

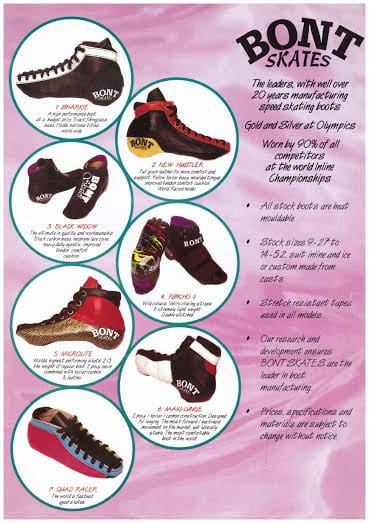

Most of the demand for other types of footwear were driven by customers. First, it was quad skaters who came to us asking if we could make them a light weight quad skate. Our quad skates were very popular all the way up to the change over to inlines in the early 90’s.

When the inline boom took off, most skaters used our short track ice boots for inline skating. We had so many orders that we had to keep expanding the back garage until we had 16 employees working in the backyard. Once we outgrew the backyard, we rented a factory in the Sydney suburb of Kingsgrove which was handy because there was a skating rink in the same street.

It wasn’t long before we also outgrew that factory and settled into a much larger facility in the adjacent suburb of Campsie. We had wanted to make cycling shoes for some years before we actually got around to it. The delays were caused by us launching our clothing company in Australia and the other issue was that the wages were so high in Australia that our cycling shoes would cost around $900 a pair to make them so the market would be too small.

We got contacted by Chris Hoy of the Great Britain who was the best track sprint cyclist in the world because his shoes were flexing under his enormous power. It started the cycling production in motion for us and helped us make the decision to go and live in China for a year to set up a factory to move our production to a location where we could produce affordable skates and shoes.

How many people work for Bont?

We have had up to 350 employees working for Bont but we have recently sold the cycling division to an investor so we now just have around 80-90 employees.

The cycling division was very successful so why sell it?

We started making cycling shoes in 2006 and in this short time we won every accolade possible. We won 14 Olympic gold medals on Bont shoes, the Tour de France as well as every other famous cycling race. The brand was growing very quickly and it was really consuming my life and taking me away from my passion which is the skates.

I found that I was neglecting my real passion and I missed working in the skating industry. So, I felt it was time to let the cycling brand go so I could get my focus back to what I love.

Where are your best markets? South America, Asia…?

We are lucky in that we make a wide variety of skates so no matter if one country has big sales and another one drops off, our sales are always pretty consistent over the years. We sell quite a lot of skates to South America, but Europe, the US and Asia are all very good markets for us. We sell to 64 countries in all. We have very long term relationships in many countries.

Tell us about where the Bont logo came from…

The first logo we had was SUPER BONT. It was the name of our first model. It was just a bold font with super on top of Bont. After a few years we developed a logo that was a yellow sticker with a green map of Australia and a skating kangaroo with the name Bont inside the kangaroo. It was a really popular logo and many skaters wanted to buy skates with the yellow circle logo on it. Unfortunately. many of our competitors knew this and we had many of them copy the logo but they changed the Bont to their Brand. Their boots and logo looked so much like ours that we had skaters sending broken boots made by our competitors to us to fix because they thought they were Bont boots. We had enough so we changed the logo to just the worlds Bont Skates so no one could copy that. The logo then evolved into the one we have today which is made up of the letters B O N T which are made in the shape of a wheel to represent inline and each letter is a boot with an ice blade on it to represent an ice skate.

What is your next goal?

We recently set up our second factory in China which is aimed at producing lower cost skates. We are streamlining our ordering system and working a lot on improving manufacturing times of semi custom skates. We always have a lot of new products in the pipeline and now with more time on my hands we will have more than we did for the last few years. We are at a point where we are very comfortable with the rate of new products matches the size of the market. We have very good internal engineering that ensures that we have very few quality issues and that is an advantage for us.

How do you see the future of inline speed-skating?

As there are less speed skaters now than there were 10 years ago, we must work within the constraints of the market. That means picking and choosing projects that we know will be successful and not spending too much on our pro teams. I think the size of the market for inline speed skating has now plateaued and we think that the market size will not change very much over the next few years. We still see growth in emerging markets and we think we can help propagate the growth with good quality, comfortable and affordable skates.

Bont now proposes roller derby skates. Do you plan to enter on other markets such as fitness skating, freestyle or even aggressive?

In the early 90’s we didn’t have any orders for quad skates. I think it was around 1993, not one single order came in. People would tell me that it is a shame that Bont stopped making quad skates but we didn’t stop making them, people stopped ordering them.

When the derby craze exploded in the US a few years ago, we already knew how to make the skates because the ones we make now are very similar to the ones we won all the world titles on in the ’80s.

We just had to make some adjustments for the needs of derby skaters. I am quite surprised that a lot of the established brands in derby still persist with the old manufacturing techniques when they can see that the Bont boots are lighter, stronger and have more performance. It has been good for us that they have not copied our boots because we have captured most of the top end of the US derby market and we now have big plans for Europe.

What do you think are Bont’s strengths and weakness’? Why has Bont stuck around all these years when many brands have stopped making skates.

All of our competitors have a large number of skaters on their doorstep that they can sell to. But in Australia, the market is very small so we do not enjoy the benefit of being able to sell skates to our local market. I think the biggest strength that we have is that we have been making quality skates for 40 years. Many of the shops and coaches have been in the industry for just as long and they know that if they buy Bont skates that they will get a product that is comfortable, long lasting and great value for money.

The second advantage that we have is that we are the only company that mass produces one piece boots. The two pieces method of making boots is what our competitors use. It is an easier, cheaper way to make skates but we feel that the end product is not as good. All skate manufacturers use the one piece boot making for their custom boots, but they use the two piece method for their mass produced skates.

The third strength that we have is our great team of employees and distributors. We have a lot of people that we really feel are part of our family and they treat us like family too. This comes naturally for us being a family company.

Lastly, we give the customer more product than our competitors for the money. A lot of our competitors charge the same amount for a product as we do but our components are always better for the same price. If you take an entry level frame, many manufacturers use frames not made on a CNC machine and they use 6000 series axles. For the same price, the Bont frame will be made by a CNC machine and use 7000 series axles. We make less margin than our competitors but we have a better product and that keeps customers happy and coming back for more.

Thank you Alex!

Links

Testing quads Bont Hybrid Package

Testing Bont Wheels – Mayhem 110 mm 85A

Testing Bont Vaypor 3D – 3 points